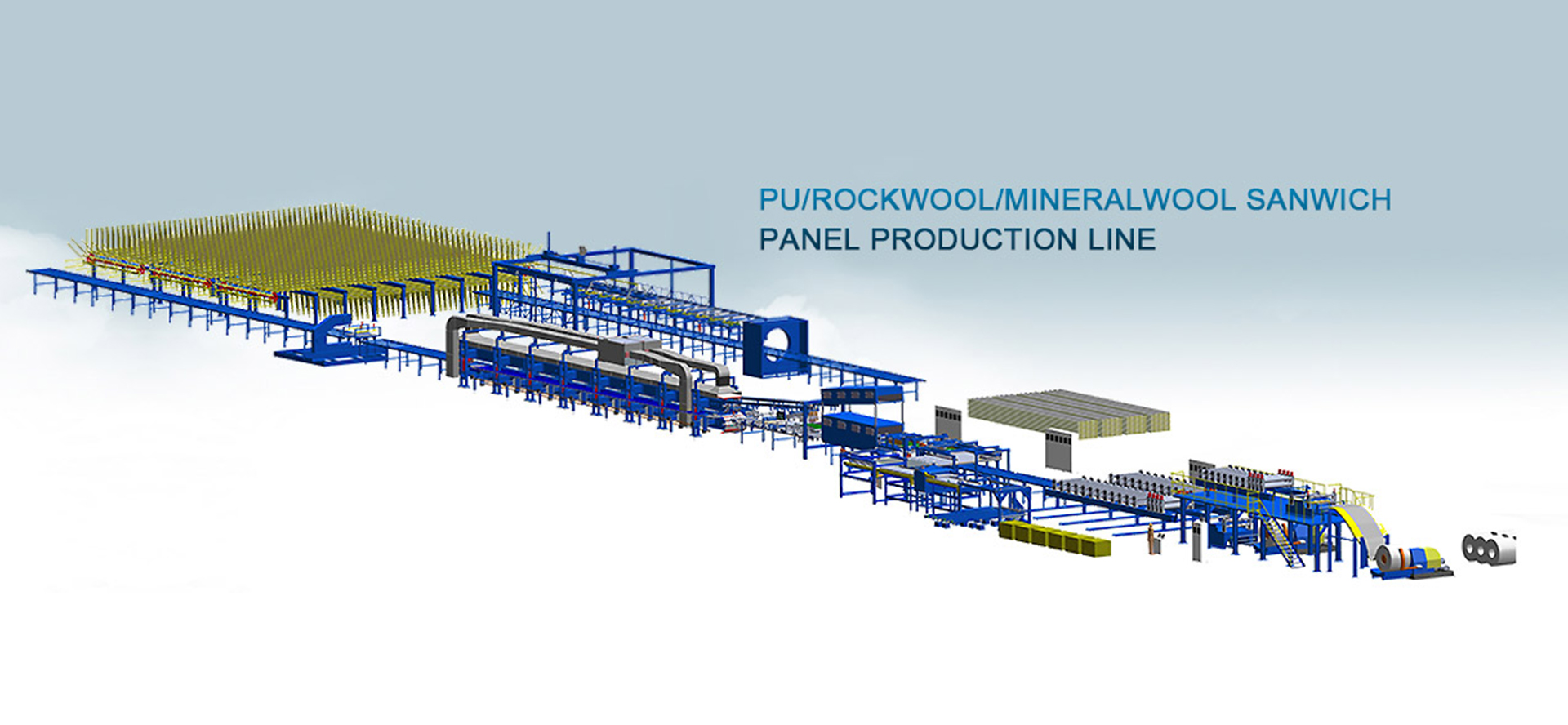

Advanced Sandwich Panel Production Line for Modern Construction

What is a Sandwich Panel Production Line?

A sandwich panel production line manufactures pre-insulated panels commonly used in walls, roofs, and cold storage facilities. These panels typically consist of two metal facings with a polyurethane (PU), polyisocyanurate (PIR), or mineral wool core. Modern production lines focus on high efficiency, consistent quality, and automation to meet the demands of large-scale construction projects.

Core Equipment in a Sandwich Panel Production Line

- Uncoiler Machine: Feeds metal sheets into the production line smoothly, ensuring continuous operation without stops for coil changes.

- Roll Forming and Laminating Machine: Shapes metal sheets and sandwiches the insulation core between them. Precise forming ensures panel durability and consistent thickness.

- Cutting and Stacking System: Finished panels are cut to length and stacked automatically. Automated stacking reduces labor costs and minimizes handling damage.

- Double Belt Press (for continuous lines): Ensures uniform compression and bonding for PU or PIR panels, improving insulation performance and panel strength.

Double Belt Machine for Sandwich Panel Production Line

Advantages of a Modern Sandwich Panel Line

- High Efficiency: Continuous lines can produce large quantities of panels with minimal downtime.

- Consistent Quality: Automated control ensures uniform thickness, density, and surface finish.

- Flexibility: Capable of producing panels with different core materials and thicknesses.

- Reduced Labor Costs: Automation in cutting, stacking, and packaging reduces the need for manual labor.

- Energy Saving: Optimized heating and pressing systems lower energy consumption.

Applications of Sandwich Panels

Sandwich panels are widely used in:

- Industrial and commercial buildings

- Cold storage and food facilities

- Cleanrooms and laboratories

- Residential wall and roof insulation

Panels produced on a modern production line provide thermal insulation, fire resistance, and structural support, making them an essential material in contemporary construction.

Choosing the Right Production Line

When selecting a sandwich panel production line, consider:

- Production Capacity: Match line speed and panel dimensions to your business needs.

- Automation Level: Higher automation reduces labor dependency and improves consistency.

- Support and Maintenance: Choose a supplier that provides installation, training, and ongoing technical support.

- Core Material Options: PU, PIR, and rock wool cores have different insulation and fire resistance properties.

Conclusion

Investing in a modern sandwich panel production line allows manufacturers to produce high-quality, reliable panels efficiently. With the right equipment, companies can meet market demands, reduce costs, and maintain consistent product quality for a variety of construction and industrial projects.